Vacuum bagging

|

BFG Architecture uses a variety of methods to produce FRP parts. Our experienced engineers will select the best method for your project based on factors such as production volume, parts dimensions, budget, and other requirements.

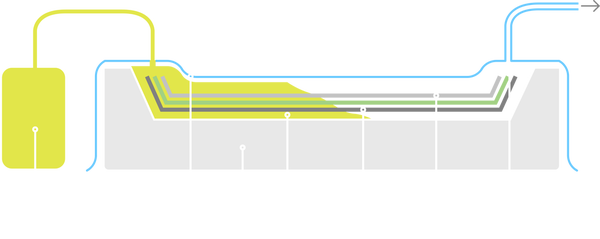

Our extensive experience with vacuum bagging moulding enables us to produce innovative and cost effective parts for our OEM customers. The process is best suited for low production volumes where a one-sided finish is required. Process Vacuum bagging is typically used on very high performance composites parts when reinforcements are “pre-impregnated” with resin to produce extremely accurate fibre-to-resin ratios. Once the fibres are wet with resin, cut to shape, and placed into the open mould, a vacuum bag is placed over the uncured composites. The air is then removed, and atmospheric pressure is used to consolidate the laminate and reduce the void content as well as the excess resin. Usually this technique is only used to achieve very high strength laminates. Under the proper circumstances, it can produce parts whose properties and quality exceed those possible with even vacuum infusion, although the two techniques increasingly overlap. Materials Resins: Primarily epoxy and phenolic. Polyesters and vinyl esters may have problems due to excessive extraction of styrene from the resin by the vacuum pump. Fibers: The consolidation pressures mean that a variety of heavy fabrics can be wet-out. Cores: Any Advantages - Higher fibre content laminates can usually be achieved than with standard wet lay-up techniques, resulting in stronger, stiffer products - Lower void contents are achieved than with wet lay-up. - Better fibre wet-out due to pressure and resin flow throughout structural fibres, with excess into bagging materials. Limitations - The extra process adds cost both in labour and in disposable bagging materials Applications - Large, one-off cruising boats, race car components, core-bonding in production of boats. |

Contact us today so we can begin discussing your project needs.

CONTACT US