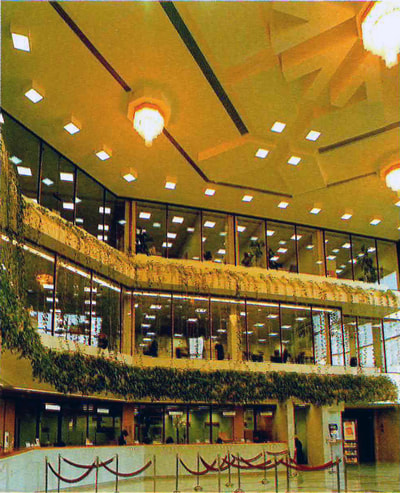

Interior Architectural Elements

|

A great looking exterior can draw people to your building, but it’s the quality of the interior that makes them want to stay.

BFG Architecture offers a wide array of items to compliment contemporary interior decors, including benches, tables, decorative panels, kitchens, bathrooms, floor tiles, fireplaces, and planters using GRC, UHPC, and FRP. The materials offer high mouldability and superior strength, which allows designers free rein with their imagination and makes previously impossible designs to come to life. You can create, for example, extremely thin table tops with perforated or solid surfaces, which create a striking first impression.

FRP, GRC, and UHPC are available in a limitless variety of custom finishes: designers can recreate the look and feel of natural materials such as wood, stone, or metal at a fraction of the price and in designs that would be prohibitively expensive or impractical otherwise. Specialised liners in the precast moulds are used to create effects such as crocodile or lizard skin, wood grain or a perfect, polished look. The applications are limited only by your imagination—BFG Architecture offers unique tailormade solutions for floors, walls, furnishing elements, accents, countertops, work surfaces, pillars, columns, sculptures, and much more. Whether you are looking to elevate the aesthetic value of a new project or breathe new life into a restoration or renovation project, BFG Architecture’s highly experienced team of experts can help you choose the best material for your project based on your budgetary, aesthetic, and functional requirements. |

Contact us today so we can begin discussing your project needs.

CONTACT US