Light Resin Transfer Moulding (LRTM)

|

BFG Architecture uses a variety of methods to produce FRP parts. Our experienced engineers will select the best method for your project based on factors such as production volume, parts dimensions, budget, and other requirements.

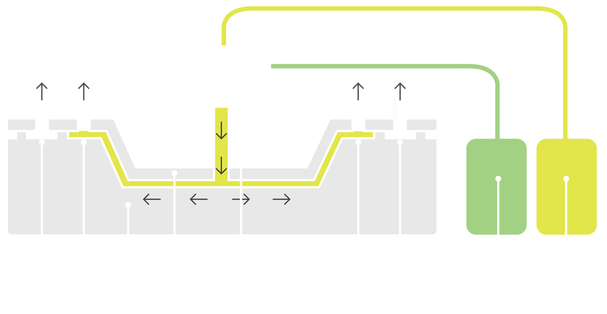

Our extensive experience with Light Resin Transfer Moulding (LRTM) enables us to produce innovative and cost effective parts for our OEM customers, including Alstom and Bombardier Transportation. The process is best suited for high precision parts where a two-sided finish is required, and for moderate production quantities, ranging from 100 to 7,000 parts per year. Process LRTM is a closed mould process. The LRTM mould consists of a rigid “A” side mould (base mould) and a lightweight semi-flexible “B” side mould (counter mould) that is sealed to the “A” side mould using vacuum pressure. Resin is drawn into the resulting cavity under vacuum. The resin infusion may be assisted by a resin injection pump, which will accelerate the infusion process. Once an “A” side mould is cured, the “B” side mould is removed and the part is demoulded from the “A” side mould. Once the glass reinforcement is fully saturated or “wet out,” the laminate is compacted with specially designed rollers and brushes to remove air bubbles and distribute the resin evenly. Multiple layers, or plies, of laminate are built up in sequence, often with a core material in the middle, to reac h the desired thickness. Various inserts, ribs, fasteners, or other items can be incorporated in the moulded part. Following a curing cycle, the part is de-moulded and trimmed as required. LRTM production is more efficient than most other processes. You can use a single “B” mould in conjunction with multiple base moulds to achieve production rates of up to three moulded parts per hour. In this case there are three “A” moulds, which move from the mould prep area through the production cycle, while the “B” mould remains in a fixed location. Materials options Resins Generally epoxy, polyester, vinylester and phenolic, although high temperature resins such as bismaleimides can be used at elevated process temperatures. Fibres Any. Stitched materials work well in this process since the gaps allow rapid resin transport. Some specially developed fabrics can assist with resin flow. Cores Not honeycombs, since cells would fill with resin, and pressures involved can crush some foams. Advantages - LRTM tooling costs are a fraction of the price of equivalent RTM moulds. - High productivity—mould cycles can be as fast as 20 minutes per part using a single “B” side mould and three “A” side moulds. - It is possible to achieve cosmetic surfaces on both “A” and “B” side of part. - High fibre volume laminates can be obtained with very low void contents. Limitations - The process is generally limited to smaller components - Not suitable for parts with negative draft - Part thickness is fixed at the time of mould construction - Glass-resin ratios of less than 35% Applications - Small complex aircraft and automotive components - Train seats |

General Design Guidelines

|

Contact us today so we can begin discussing your project needs.

CONTACT US